TL;DR: We’re moving on the 15th & 16th October. Please box up your member storage (or take it home for safe storage) and lend a hand on the day.

As you are well aware by now, Leeds Hackspace is preparing to move up the road to Unit 14, Sheepscar House. The time has come to commit to the new building and start using it as our full time premises.

We will be moving the current Hackspace from Mabgate Green to the new building on the weekend of the 15th and 16th October.

This is a major undertaking, and when we say we need as much involvement from the membership as possible we aren’t joking.

What do I need to do?

- Member storage must be disappeared, or boxed before move date.

If you can take it home, please do! The less we have to move the better. If you aren’t able/willing to take the contents of your member storage home please at least box it, then label it. Just like when it is stored at the Space we don’t take any responsibility for things which are lost or broken during the move.

- Sort out some rubbish

The to-hack pile has a lot of extraneous rubbish in that nobody will ever use. Take a look through and place anything you think will be genuinely useful in the “To Hack Keep” boxes that will shortly be appearing in the Space. Everything else will not be brought with us.

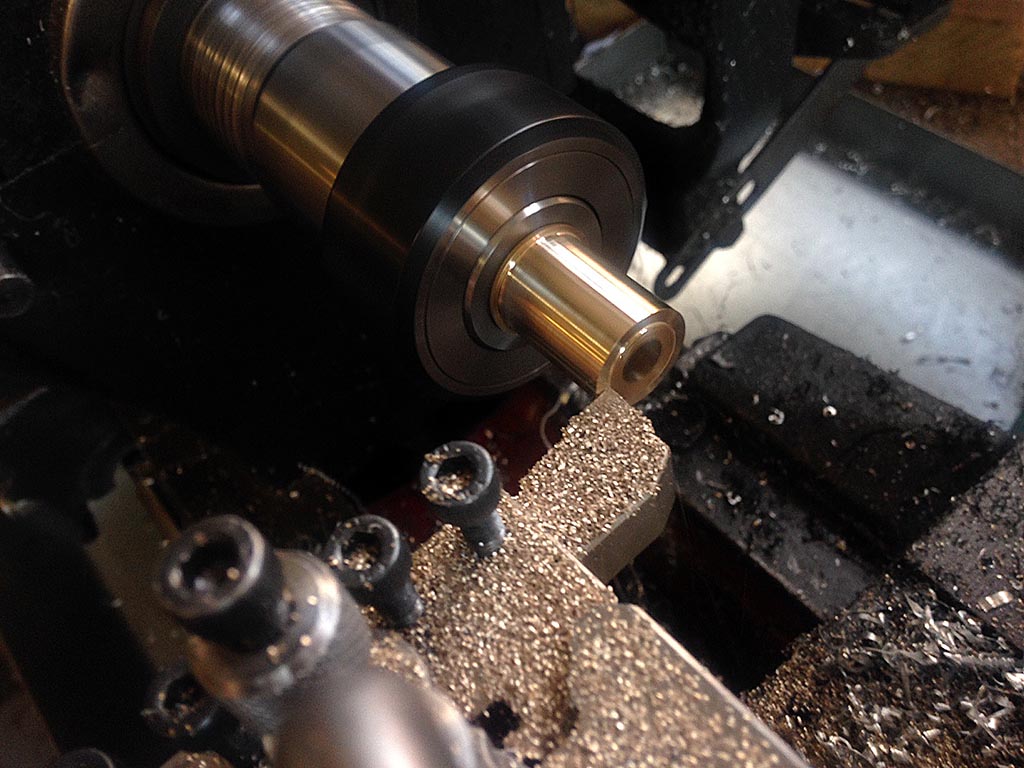

- Responsible for a thing? Get it ready for the move.

Are you responsible for a thing, like the laser cutter, or a 3D printer, or a display screen? Make sure that everything is well labelled, any spares are boxed together and labelled sanely so that we can just pick it up and go.

- Got moving equipment?

Do you have machinery skates, or stair climbing sack trucks? Fantastic, can we borrow them please?

Wait a second, is the space even finished?

It’s very close, it just needs the final touches. We’re getting an electricity supply installed shortly, and the actual electrical installation will be completed very soon. At the very least the utility provision will be no worse the current Space. Did I mention that the new Space has three toilets and two sinks?

Still do do is floor, door and electrics. Busy stuff, but we can do it!

There will be disruption over the next few months as we rearrange and build furniture, but this is stuff we need to do once we’ve moved in.

What else do I need to know?

There will be no advertised open night for the general public on Tuesday 18th October, we’ll still be unpacking and getting things sorted. All members are of course welcome on the night to get the unpacking moving forward at a reasonable pace.

The days leading up to the move will be busy – essentially from the 11th October the Hackspace will be closed for personal projects. Please come along and help pack boxes and things instead.

There will be a party!

Probably in November. Date TBC.

Thanks, see you in October!

Leeds Hackspace Management Committee