It has been a long time since our last update but that doesn’t mean that we haven’t been working hard. For those of you who haven’t visited lately it’s looking much less like a building site and we are getting closer to the Hackspace being “finished”. Yes, we really do deserve a good opening party.

Health & Safety

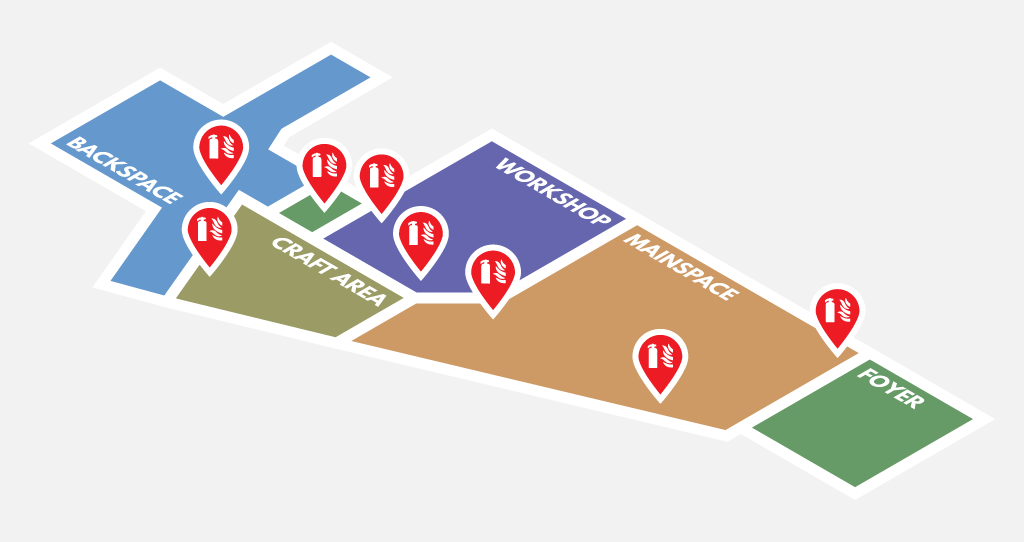

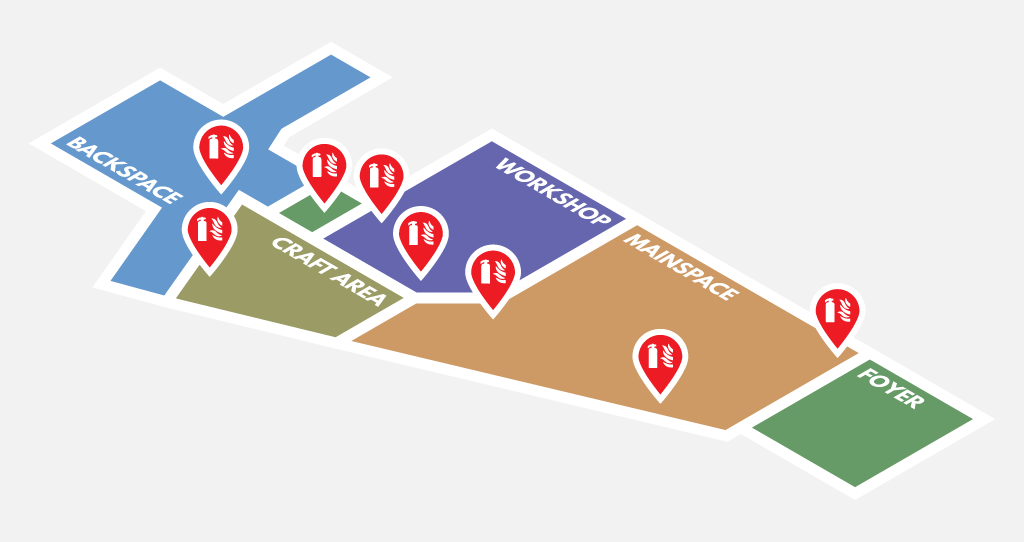

You may have noticed the fire extinguishers scattered around the Space. Please take time to familiarise yourself with them next time you are down and remember if you are not confident in their use before you see a fire, walking away and out of the building is recommended over choosing that moment to try and learn from the instructions on the side.

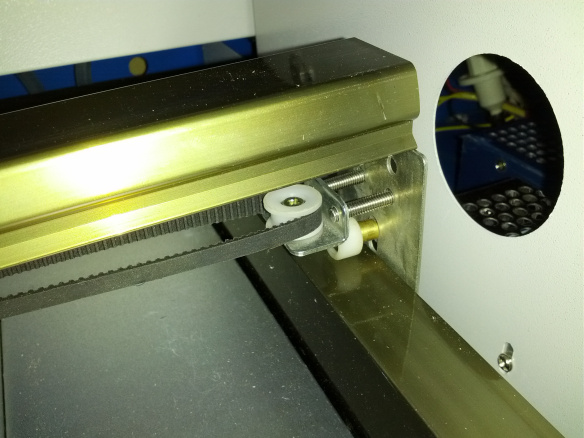

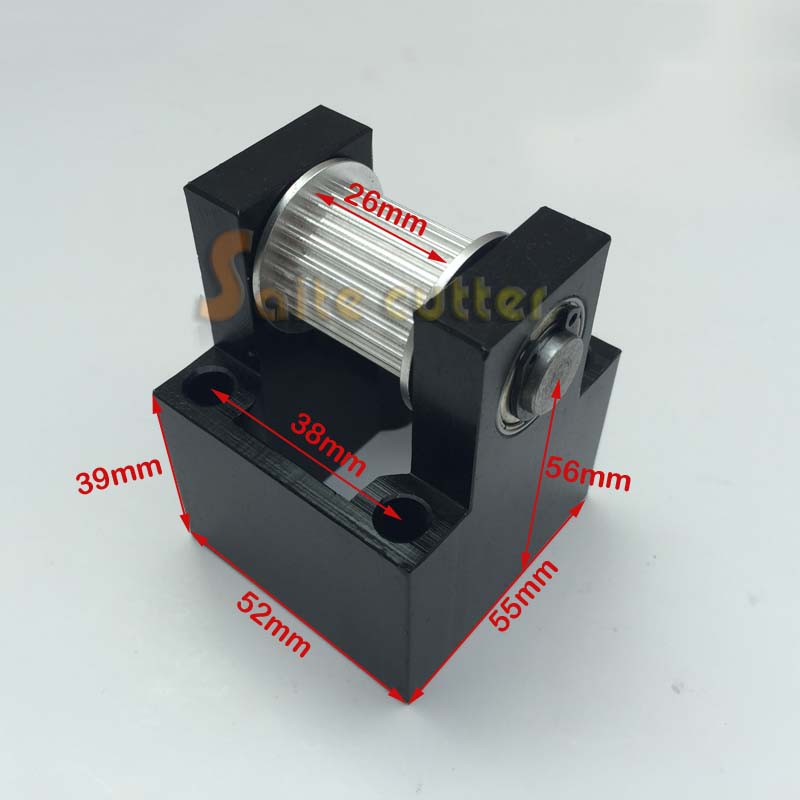

PPE has been made more obviously accessible in the Workshop and we are adding signage to offer guidance on when usage is appropriate.. We are also looking to fit an extraction system so we can move the Laser Cutter to the craft area and get the wood lathe set up in the workshop. In the meantime we continue to accumulate shiny tools (like the long term loan of the sheet metal bender/roller/slicer, thank you Ben) and we are in the process of updating our risk assessments. In the future we will be looking at expanding the Tool Access Node system currently in use on the Laser Cutter so that more tools can be controlled.

The electrical install is mostly in place with their appropriate certifications thanks to the efforts of Adam and Tim. The final piece will hopefully be put in place on August bank holiday in the form a submain cable to improve our earthing. In the meantime we can use what is in place so far confident that it is safe and of good standard.

To improve general security a number of internal CCTV cameras have been put up. These will not be available to view outside of the Hackspace, but a select few may be presented on the Sauron screens in a manner similar to how they were before the move. Viewing of camera feeds from outside the Hackspace is unfortunately incompatible with our responsibilities to the Information Commissioner’s Office and the Data Protection Act.

Building Works

Stephen is blazing ahead with the kitchen, and so we hope soon to have flowing water and an nice place to bake cakes and make cups of tea.

The network is being installed thanks to Nav, with only a small amount of cable-management related swearing. He has also made a start on the Darkroom. When the committee get a chance they will be taking a look at how we can manage the chemicals and waste products from photo processing in a safe and legal manner. Once that’s done we can get started!

We’re also working on upgrading the door system – thanks Callum, Alex, Joe and Fligg – to allow our bionic members to better integrate with the system, improve security and a couple of bits to make setup for new members and removal of old members easier.

Storage

The member storage system seems to be working well so far with only a couple of pieces being placed in the Big Box of Shame. For those of you with a large number of separate, distinct items in your storage please seriously consider purchasing a 35L Really Useful Box to help protect your items from loss or damage should we have to relocate anything. There are a few larger member items still in the space that Joe is working on better solutions for them.

Please remember that that flammable items (including spray paint, varnishes etc.) must not be stored in the member storage. Instead these should be labelled and placed in the appropriate cabinet in the Workshop.

New bins have arrived from AWM – if you haven’t yet had a chance to utilise them please do. Both will be emptied fortnightly, although there is potential to increase the frequency of pickups (“lifts” as the waste management industry calls them) so do let us know if you think they are getting too full for comfort. These particular bins don’t automatically lock so please remember to do so!

The red topped bin is for general waste; the blue topped one is for dry mixed recycling. In short put plastic, metal, paper and card in the blue bin and everything else in the red one. The general waste bin has a weight surcharge on it – everything over 40kg costs a small amount extra to dispose of – so please recycle as much as you can. The Hackspace is being kept tidier as bins are actually being emptied – thank you for your help with this, it really does make a difference.

Anything else?

In terms of membership we must be doing something right as we are on the up, so again a big thank you to everyone that helps to make our new members feel welcome and get them using the tools they need. We currently have 78 members!

Behind the scenes we continue to pay the bills and ensure that we can afford to pay the bills. Thanks to the efforts of Matt and Harriet in keeping us solvent.

Can we remind you of the resolutions services offered by George and Ari if you feel things you want to change are getting bogged down or communications are breaking down with other members then we recommend contacting them. But as ever if you have any concerns you feel that need addressing or questions for the committee you can always email us or ask us via the chat room or in person.

That’s all for now folks, it won’t be quite as long until the next update.

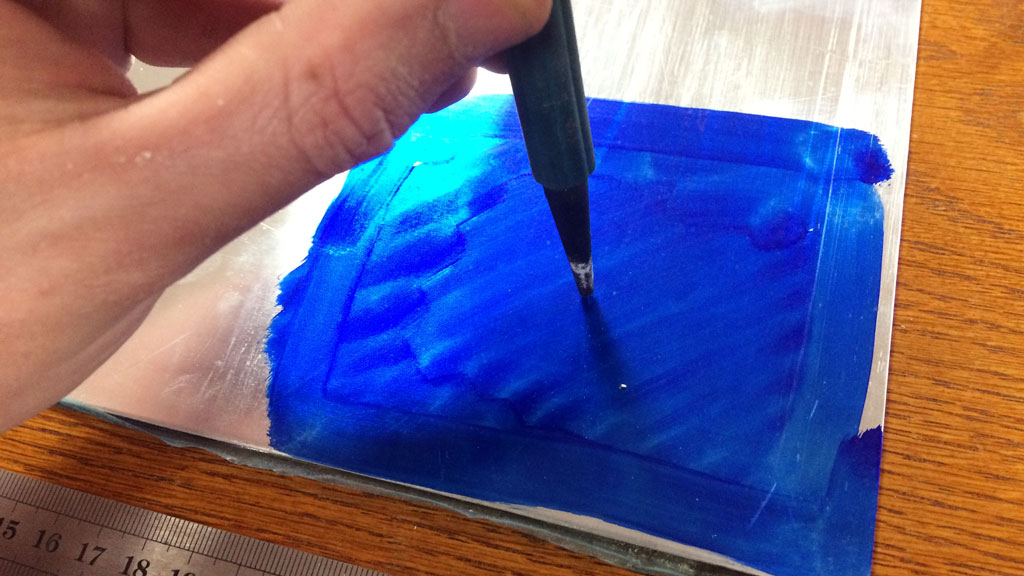

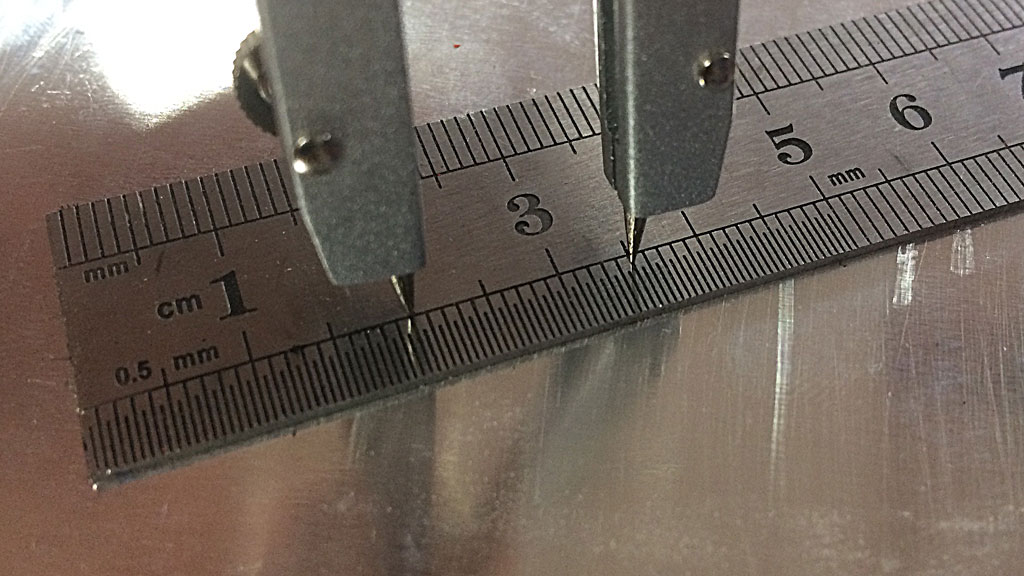

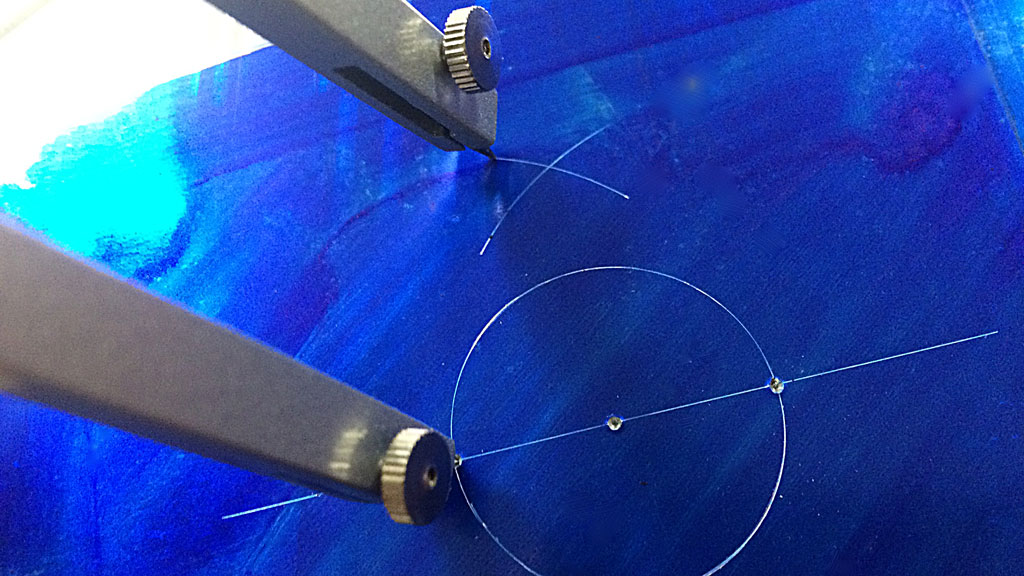

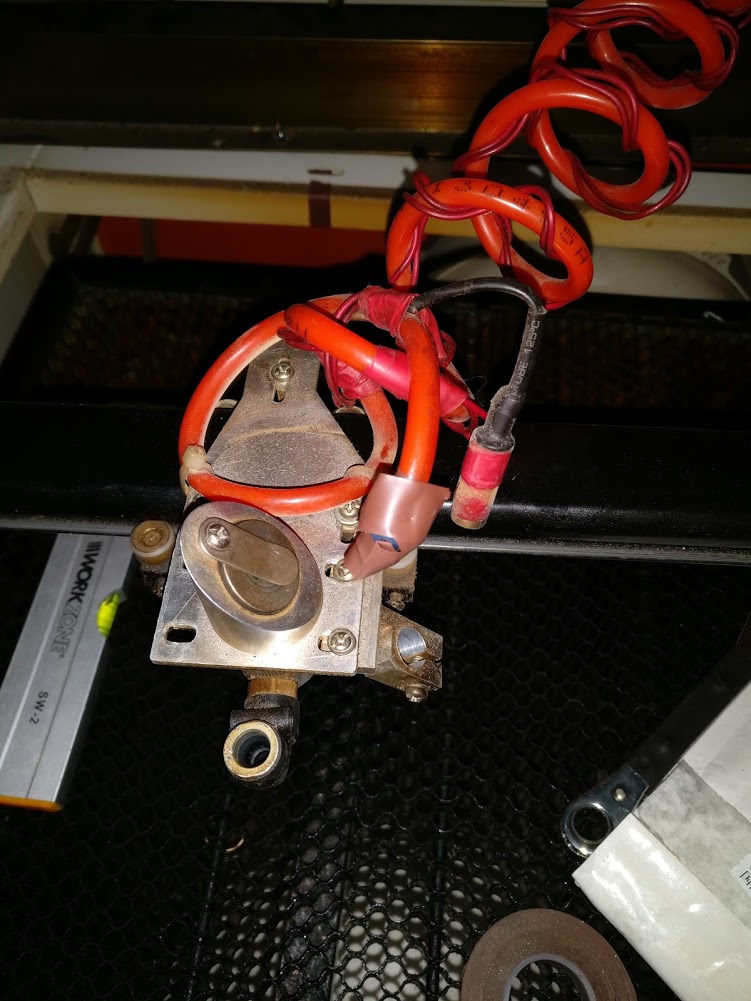

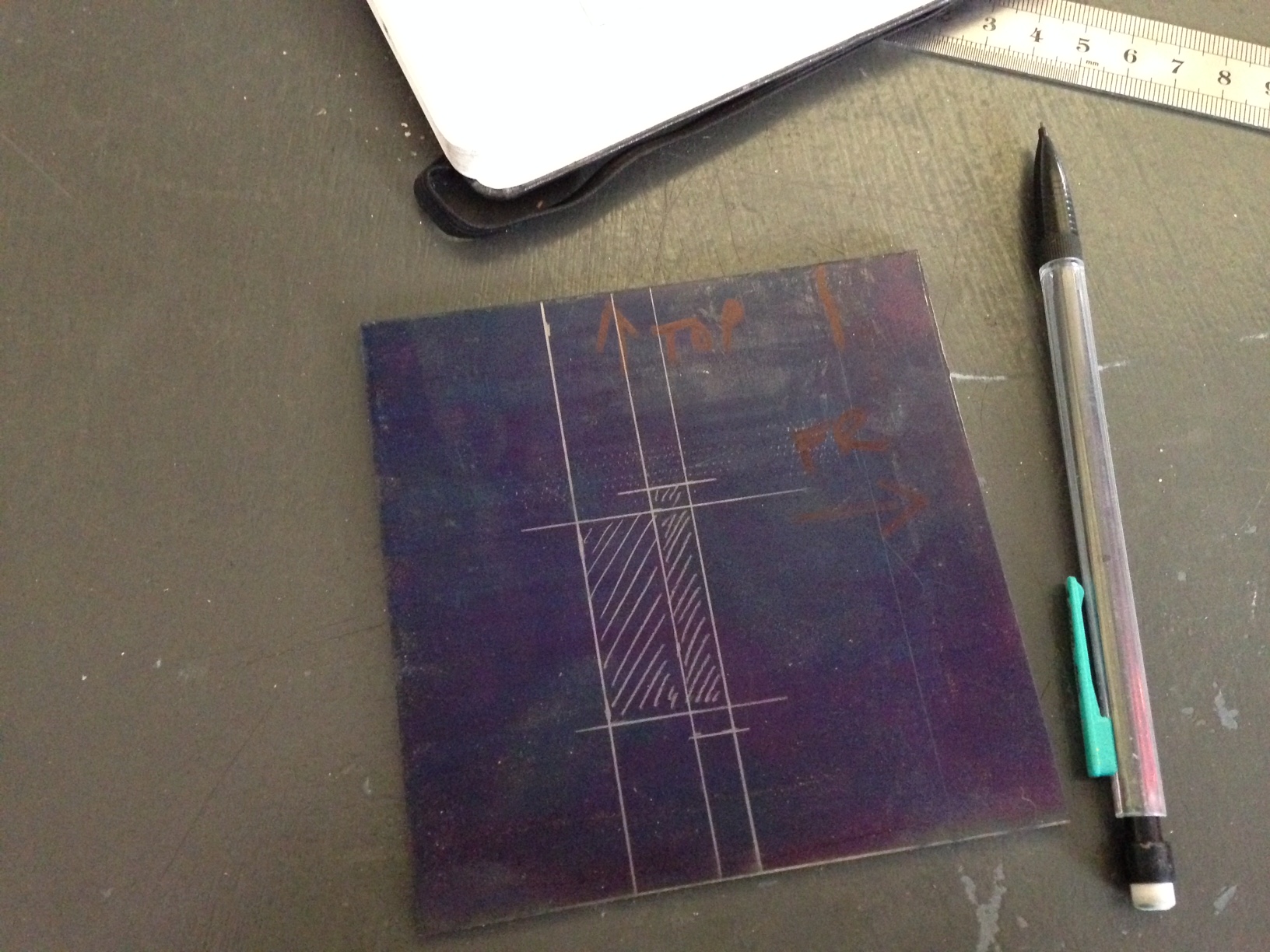

I started pewter casting as I do medieval living history reenactment and wanted to demonstrate a trade in the way it was done in the 15th Century. The stone moulds I create and techniques used are all based on evidence I’ve researched from the period. I’ll be heating the pewter on a modern heater for the demonstration as charcoal isn’t the safest indoors. If you would like to know more just ask on the day.

I started pewter casting as I do medieval living history reenactment and wanted to demonstrate a trade in the way it was done in the 15th Century. The stone moulds I create and techniques used are all based on evidence I’ve researched from the period. I’ll be heating the pewter on a modern heater for the demonstration as charcoal isn’t the safest indoors. If you would like to know more just ask on the day.